From quartz block to quartz wafer 从石英晶体毛坯到石英晶片

First of all, the reference plane Z of the block is surface-ground. After grinding, the Z-plane of the quartz block is precisely defined and the block can be further processed.

首先,石英毛坯的参考平面Z是地表。研磨后,石英晶体毛坯的Z平面被精确定义,可以对块体进行进一步加工。

Now, so-called quartz wafers are cut from the block. The direction of sawing is along the X-axis. We recall: This is then reused for cultivating synthetic quartz.

现在,从块上切下我们所说的石英晶圆。锯切的方向是沿X轴。然后将其重新用于培养合成石英。

Quartz wafers are cut out from the quartz block.

From quartz wafer to quartz blank 从石英毛坯切割出石英晶圆

Now, small crystal blanks are cut from the wafer. The desired cutting angle here is 35 ° – this is also referred to as the “AT cut”. Read about why this particular cutting angle is important here.

现在,从晶圆上切下小晶片。这里所需的切割角度是 35°——这也称为“AT 切割”。在此处了解为什么这个特定的切割角度很重要。

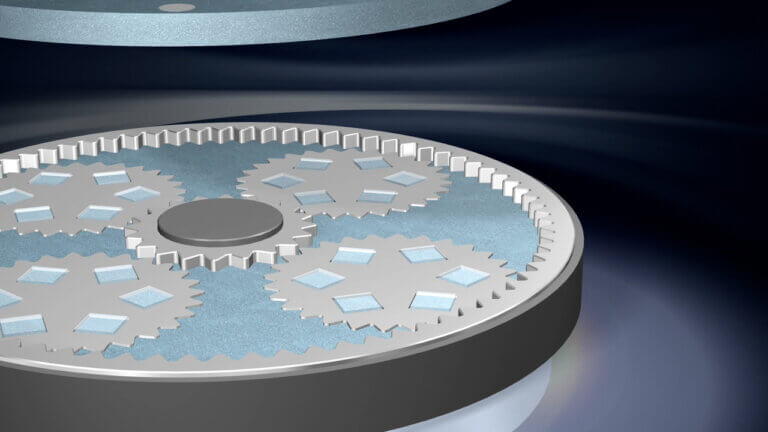

The quartz blanks are then lapped in a plane-parallel manner until the desired thickness is achieved. This depends on the frequency that the blanks should have at the end of the process. The frequency that is aimed for during this production stage is usually slightly below the final target frequency. The lobed blanks are now cut into raw blanks and subjected to grinding once again.

然后以平面平行的方式研磨石英晶片,直到达到所需的厚度。这取决于晶片在过程结束时应该具有的频率。在此生产阶段的目标频率通常略低于最终目标频率。现在将晶片坯料切割成原始坯料并再次进行研磨。

The blanks are lapped until the desired thickness is reached.

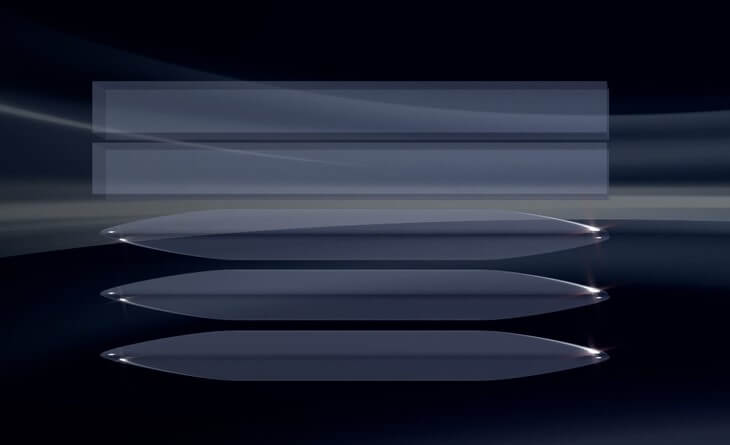

The next processing stage is called “beveling”. Once this is complete, the quartz blank is in the shape of a cushion in cross-section. On the one hand, this shape enables easier installation in holder systems and, on the other hand, the vibrating area of the blank is reduced. This avoids spurious resonances. Quartz blanks before and after bevelling. The characteristic shape of a lense can be seen.

下一个加工阶段称为“倒角”。完成此作后,石英坯料的横截面呈垫形。一方面,这种形状可以更容易地安装在支架中,另一方面,晶片的振动面积减少。这避免了杂散谐振。倒角前后的石英晶片。可以看到镜片的特征形状。

After beveling the blanks have the shape of a cushion.

Attaching the electrode 增加电极

After the frequency has been checked using X-rays, the quartz blanks are washed. The components are thereby optimally prepared for the application of the electrode. Again, the blanks are sorted according to their frequency, and even at this stage they should still be slightly above their target frequency. Why? Attaching the electrode reduces the frequency somewhat, which must therefore already be taken into account in the preceding stages.

使用 X 射线检查频率后,清洗石英晶片。这些组件为电极的应用做好了最佳准备。同样,晶片根据其频率进行排序,即使在此阶段,它们仍应略高于目标频率。为什么?因为所附加的电极会在一定程度上降低频率,因此必须在前面的阶段中考虑到这一点。

Finally, the electrodes are vapor-deposited through a stencil – a process also referred to as “sputtering”. The blank is now ready and can be mounted in the housing.

电极通过被银——这一过程也称为“溅射”。石英晶片现已准备就绪,可以以密封形式安装在外壳中了。