How thick is a quartz blank of 40 MHz? As thick as.. 40 MHz 的石英毛坯有多厚?

A: a fingernail 指甲

B: a normal sheet of printer paper 一张普通的打印纸

C: one hair 一根头发

Guess for yourself – the solution will come in the text. But first, let’s take a look at the theory:

自己猜猜——解决方案将在文本中出现。但首先,让我们来看看理论:

Generally speaking, there is an inversely proportional relationship between the resonant frequency of a quartz blank and the thickness of a quartz plate.

一般来说,谐振频率与石英晶片的厚度呈反比关系。

In other words – the higher the resonant frequency is to be, the smaller the thickness of this quartz blank required for it. This is due to the fact that a so-called standing wave is formed between the interfaces of the quartz disk. This standing wave builds up inside the quartz wafer through reflection on the two interfaces of the transverse acoustic wave propagating in the thickness direction. The largest mechanical displacement is in the plane of the quartz plate perpendicular to the wave propagation direction.

换句话说——谐振频率越高,所需的石英晶片厚度就越小。这是因为晶体的界面之间形成了所谓的驻波。这种驻波通过在厚度方向上传播的横向声波的两个界面上的反射在石英晶圆内部积聚。最大的机械位移位于垂直于波传播方向的石英晶片平面内。

At the resonant frequency, an odd number of half the acoustic wavelength fits in the thickness plane of the quartz blank. Therefore, the thickness of a blank is the main frequency-determining dimension of quartz produced in the AT-section. AT-section quartz crystals are commonly manufactured in the following frequency ranges:

在谐振频率下,声波长一半的奇数适合石英晶片的厚度平面。因此,晶片厚度是AT切石英晶振生产工艺的主要频率决定尺寸。AT 切石英晶体通常在以下频率范围内制造:

- 1 MHz ~ 60 MHz, operation in fundamental mode 1 MHz ~ 60 MHz,在基波模式下

- 30 MHz ~ 200 MHz, operation in overtone mode (3rd; 5th; 7th; 9th overtone) 工作 30 MHz ~ 200 MHz,在泛音模式下工作(第 3、第 5、第 7、第 9 泛音)

As mentioned earlier, the required thickness d of a quartz plate (blank) can be estimated since an odd number of half-wavelengths should fit in the thickness plane of the quartz blank.

如前所述,可以估算石英晶片所需的厚度 d,因为奇数个半波长应适合石英晶片的厚度平面。

In addition to the thickness of the quartz blank, the propagation velocity v of the acoustic wave in the quartz material must be taken into account in order to calculate the resonance frequency f. For AT-section quartz, the propagation velocity v is about 3320m/sec. Based on this, the required thickness d at a given frequency can be estimated as follows:

除了石英毛坯的厚度外,还必须考虑声波在石英材料中的传播速度v,以计算谐振频率f。对于AT切石英晶体,传播速度v约为3320m/sec。基于此,给定频率下所需的厚度 d 可以估计如下:

d ≈ n x ½ x v/f with n = 1, 3, 5,…

In the fundamental mode, the following thicknesses of a quartz blank will be obtained at the frequencies of 10.0 MHz and 40.0 MHz:

在基波模式下,在10.0 MHz和40.0 MHz频率下将获得以下厚度的石英晶片:

10.0 MHz ⇢ d = 166.0μm

40.0 MHz ⇢ d = 41.5μm

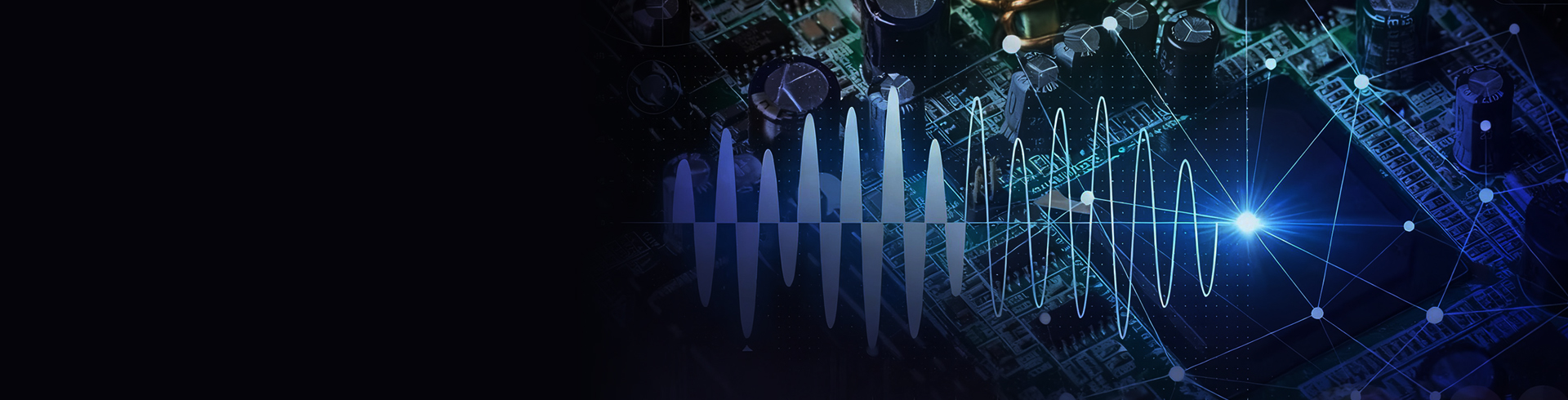

A quartz blank with a resonant frequency of 40 MHz is therefore a relatively thin disk. It has a thickness of only 41.5µm, which is about 0.04 mm. Thus, the thickness is about the diameter of a human hair and is about one tenth the thickness of a sheet of paper. So the correct answer was C. 😉

因此,谐振频率为 40 MHz 的石英晶体是一个相对较薄的晶片。它的厚度只有41.5μm,约为0.04毫米。因此,厚度约为人类头发的直径,约为一张纸厚度的十分之一。所以正确答案是C。

The close-up shows: The 40 MHz quartz blank has about the thickness of a human hair.

And how can we now ensure, for example, that the tolerance of the resonant frequency deviates from the desired resonant frequency by only ±10 ppm (parts per million)?

例如,我们现在如何确保谐振频率的容差仅偏离所需的谐振频率 ±10 ppm(百万分之一)?

If we translate this to the nominal thickness of the quartz blank, a deviation of the resonance frequency of ±10ppm would correspond to a thickness tolerance of only ±0.415 nm.

如果我们将其转换为石英晶片的标称厚度,则共振频率的偏差 ±10ppm 将对应于仅 ±0.415 nm 的厚度公差。

This is not achievable even with the most sophisticated mechanical operations. In addition, an oscillating quartz crystal is said to be a very low-cost component that will also be used in the consumer sector.

即使借助精密机械最复杂的操作,这也是无法实现的。此外,用于产生振荡频率的石英晶体本身是一种成本非常低的材质,也需要考虑其会广泛应用于消费领域这个问题。

So how is this low frequency tolerance of only ±10 ppm to be achieved?

那么如何实现这种仅 +/-10 ppm 的低频容差呢?

Instead of the mechanical tolerance, which cannot be achieved in practice, we use a trick. This is because the resonant frequency of the quartz blank can be influenced in a very small range by coupling an additional weight.

我们并没有使用在实践中无法实现的机械公差,而是使用了一个技巧。这是因为石英晶片的谐振频率可以通过简单的耦合额外的重量,使其实现在非常小的范围内受到影响这个目的。

To understand how this trick works it is important to know that the quartz blank can be excited to oscillate with the help of two electrodes. This only works because of the piezoelectric effect.

要了解这个技巧是如何工作的,重要的是要知道石英晶片可以在两个电极的帮助下被激发振荡。这只是因为压电效应而起的作用。

The two electrodes on the opposing surfaces of the quartz blank have a very small mass, which in addition to the thickness of the blank affect the resonant frequency. For this reason, the quartz blank is made somewhat thinner than calculated, since the resonant frequency drops somewhat due to the additional coupled mass of the electrodes.

除了晶片厚度外,石英晶片相对表面上的两个电极质量尽管非常小,也会影响谐振频率。出于这个原因,石英晶片比计算的要薄一些,因为谐振频率由于电极的额外耦合质量而有所下降。

After applying the two electrodes by means of a sputtering process, the resulting resonant frequency should still be just above the final nominal frequency. In the last manufacturing step before the hermetic sealing of the quartz housing, the real “trick” then takes place.

通过喷银工艺施加两个电极后,产生的谐振频率仍应略高于最终标称频率。在石英晶振外壳气密密封之前的最后一个制造步骤中,真正的“技巧”就会发生。

It consists of applying yet another extremely thin metallic layer to the existing electrode. This is done using another sputtering process while continuously measuring the resonant frequency of the quartz disk. This second sputtering process is comparatively slow and is stopped as soon as the exact nominal frequency is reached.

它包括在现有电极上涂上另一层极薄的金属层。这是使用另一种喷银工艺完成的,同时连续测量石英盘的谐振频率。第二次喷银过程相对较慢,一旦达到确切的标称频率就会停止。

“Additional mass” is applied to the blank during the second sputtering process.

This “trick” of applying a very slight additional mass in a targeted and individually controlled manner allows the resonant frequency to be set very precisely, whereby a tolerance of the resonant frequency of ±10 ppm or better can be achieved. This precision would not be achievable through purely mechanical machining steps.

这种以有针对性和单独控制的方式施加非常轻微的额外质量的“技巧”允许非常精确地设置谐振频率,从而可以实现 ±10ppm 或更好的谐振频率公差。这种精度是无法通过纯机械加工步骤实现的。