Whether medical technology, telecommunications or consumer electronics, quartz crystals have established themselves as a precise frequency generator in all industries. When energized, the thin quartz disc oscillates at a steady rate and thus determines the heartbeat of the application. While this sounds simple, the matter is quite complex because quartz blanks are not all the same.

无论是医疗技术、电信还是消费电子产品,石英晶体都已成为所有行业的精密频率发生器。通电时,石英晶片以稳定的速率振荡,从而决定应用的心跳。虽然这听起来很简单,但事情却相当复杂,因为石英晶体坯料并不完全相同。

The quartz blanks not only differ in thickness, but also in temperature coefficient and vibration behavior. If, for example, the surrounding temperature changes slightly, the stability of the frequency generated by the quartz can be negatively affected. The more the temperature changes, the stronger is the deviation from the desired frequency.

石英晶体毛坯不仅厚度不同,而且温度系数和振动方式也不同。例如,如果周围温度略有变化,石英晶体产生的频率的稳定性可能会受到负面影响。温度变化越多,与所需频率的偏差就越大。

Quartz crystals also differ in the way they vibrate. The “longitudinal oscillator” stretches along its longitudinal axis; like a rubber band being stretched. “Bending U-tube” quartz crystals, on the other hand, oscillate mainly in the middle of the blank. They behave like a bowstring that is alternately tensioned and relieved. However, the most common type of oscillation is the “thickness shear oscillator”. As shown in the figure, the upper and lower sides of the blank move in opposite directions, while the quartz disc simultaneously changes its thickness.

石英晶体的振动方式也不同。“纵向振荡器”沿其纵轴延伸;就像一根橡皮筋被拉长一样。另一方面,“弯曲 U 型”石英晶体主要在晶体中间振荡。它们的行为就像一根弓弦,交替张紧和松缓。然而,最常见的振荡类型是“厚度切型振荡器”。如图所示,坯料的上下两侧向相反,而石英晶体同时改变自身厚度。

AT Cut Defines Vibration Type and Temperature Coefficient AT Cut 定义了振动类型和温度系数

Both characteristics, the temperature coefficient and the oscillation type of the quartz, can be specifically influenced in the production process. The decisive factor is the cutting angle at which the quartz disc is removed from the crystal. Quartz crystals are cut to size based on mathematical calculations, and any change can cause serious repercussions to the quality of the part.

石英晶体的温度系数和振荡类型这两个特性都会在生产过程中受到具体影响。决定性因素是石英晶片从晶体上取出的切割角度。石英晶体是根据数学计算切割成一定尺寸的,任何变化都会对晶振产品的质量造成严重影响。

One of the most common angular cuts is the AT cut, which is used in the production of all Genuway crystals. This cut is made at 35 degrees from the Z-axis of the quartz crystal and is one of the most commonly selected cutting angles. Quartz blanks produced in this way have a good temperature coefficient. In the temperature range between -40 and 85 degrees Celsius, precise frequencies can be generated with a deviation of only +/- 15 ppm (ppm = parts per million) thanks to the AT cut. Used in an oscillator with additional temperature compensation (TCXO), these AT-blanks guarantee an even higher frequency stability of up to +/- 0,5 ppm.

最常见的角度切割之一是 AT 切割,用于生产所有晶诺威晶体。这种切割与石英晶体的 Z 轴成 35 度角,是最常选择的切割角度之一。以这种方式生产的石英毛坯具有良好的温度系数。在 -40 至+ 85 摄氏度的温度范围内,由于AT切割方式,可以产生仅 ±15 ppm(ppm = 百万分之一)偏差的精确频率。这些 AT晶体毛坯用于具有附加温度补偿 (TCXO )的晶体振荡器,可保证高达±0.5 ppm 的更高频率稳定性。

All quartz crystals produced with the AT cut are thickness shear oscillators – a great advantage for further processing. Quartz crystals are passive components, without external voltage they are completely useless. Fine electrodes must be attached to the quartz to energize it and make it oscillate.

所有采用AT切割生产的石英晶体都是“以厚度决定频率”的振荡器——这是进一步加工的一大优势。石英晶体是无源元件,没有外部电压,它们无法工作。我们必须将电极连接到石英晶体上,以使其通电并使其产生振荡。

The attachment of these electrodes, however, proves to be a great challenge, depending on the type of oscillation. Ideally, the electrodes should be attached to a point on the quartz where it deforms only minimally, even under voltage. This is much easier with a thickness shear oscillator than with the bending or longitudinal oscillators mentioned at the beginning.

然而,为其附加电极是一个巨大的挑战,具体取决于振荡的类型。理想情况下,电极应连接到石英晶体上的一个点,即使在电压下,石英晶体的变形也仅最小。使用厚度切割型晶体振荡器比使用开头提到的弯曲或纵向振荡器要容易得多。

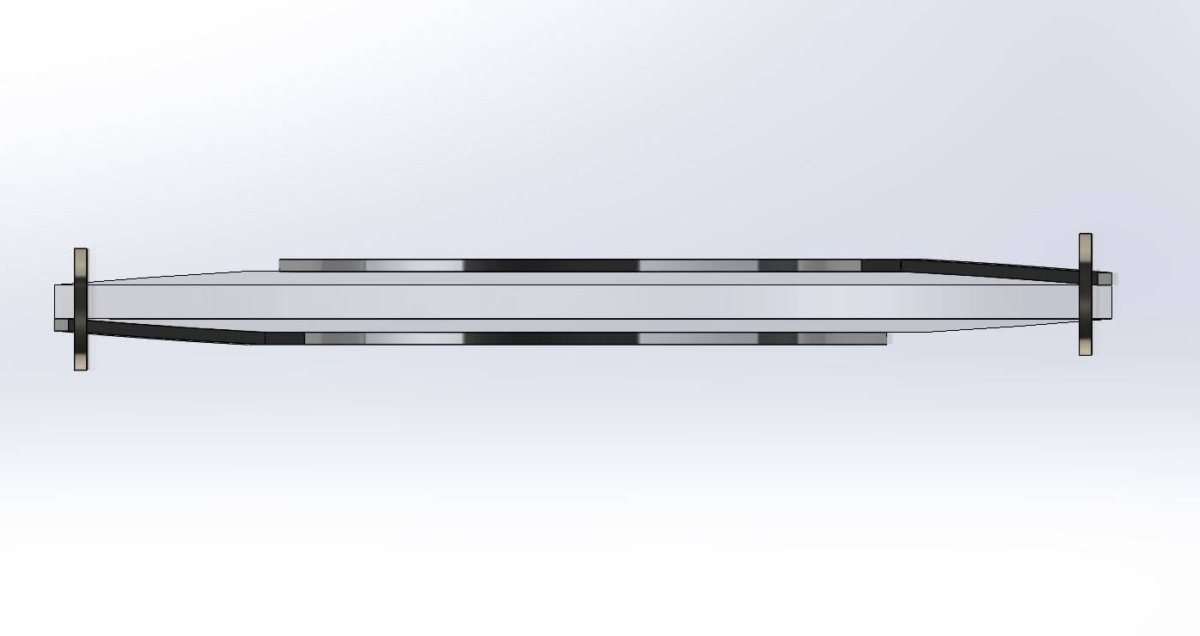

Nevertheless, a further processing step of the quartz is also necessary. In a special lapping machine, the blanks are ground until they assume the shape of a cushion – slightly thicker in the middle and tapering outwards. The quartz holder is attached to the tapered ends. Secured in this way, thin metal electrodes are finally evaporated onto the thicker middle section of the blank.

然而,对石英晶片的进一步加工步骤也是必要的。在一台特殊的研磨机中,坯料被研磨,直到它们呈现出垫子的形状——中间稍厚,向外逐渐变细。石英晶体支架连接到锥形端。以这种方式固定,金属电极最终以“被银溅射方式”附着到晶体坯料较厚的中间部分。

The AT cut thus fulfils a double function in quartz production. First, it ensures high frequency stability in the temperature range from -40 to 85 degrees Celsius and second, it defines the shape of the blank as a thickness shear oscillator.

因此,AT 切割在石英生产中发挥了双重功能。首先,它确保了-40至+85摄氏度温度范围内的高频稳定性,其次,它将毛坯的形状定义为“厚度剪切型”振荡器。