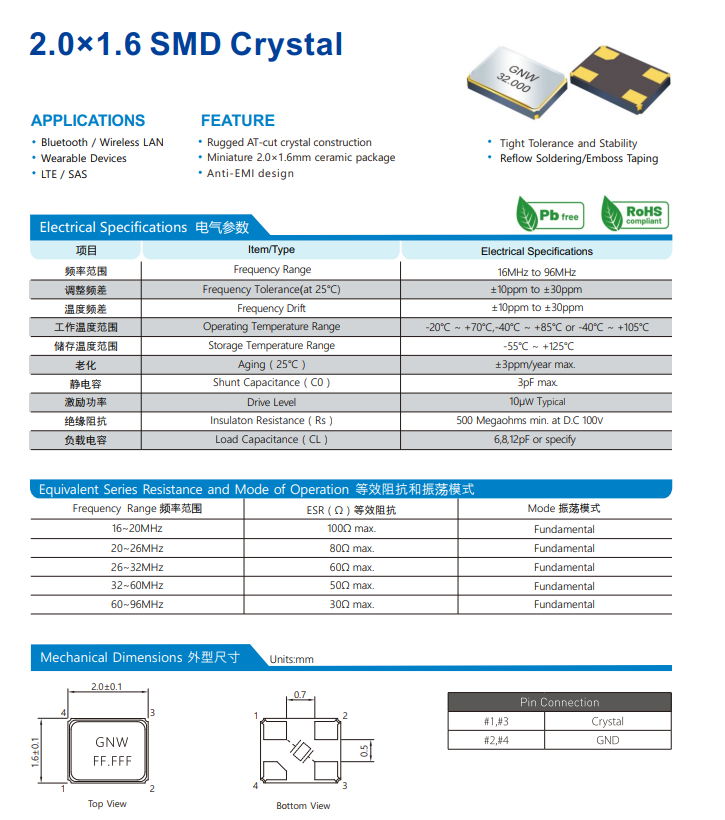

A major requirement for quartz crystals in wireless applications is naturally their frequency accuracy. Circuits are normally assigned radio wavelengths in narrow frequency bands. To prevent interference from other frequencies and also to enable connections over longer ranges, it is important that any wandering from the nominal frequency is kept to a minimum. In Bluetooth, for example, the maximum permitted frequency deviation is ± 40 parts per million (ppm). This limit must not be exceeded at any point during the entire lifetime of the application under any circumstances. To ensure this, the developer must estimate all possible influences using a worst-case calculation, thus, in particular:

无线应用中对石英晶体的一个主要要求自然是它们的频率精度。电路通常在窄频带内分配无线电波长。为了防止来自其他频率的干扰并实现更远范围的数据连接,重要的是将任何偏离标称频率的偏差保持在最低限度。例如,在蓝牙中,允许的最大频率偏差± 40ppm。在任何情况下,在应用程序的整个生命周期内的任何时候都不得超过此限制。为确保这一点,开发人员必须事先考虑到最坏情况,然后来估计所有可能的影响,因此,特别是:

- Tolerance at 25°C 常温+25°C 时的容差

- Stability across the expected temperature range 在预期温度范围内保持稳定性

- Error resulting from mismatch of circuit CL 电路CL不匹配导致的错误

- Long-term changes 长期变化

- Error resulting from tolerance of load capacitance (= CL deviation) 负载电容容差产生的误差(= CL 偏差)

- CL tolerances of pin capacitances on the IC, plus PCB tolerances IC上引脚电容的CL容差,加上PCB容差

To ensure frequency compliance at 25°C, the load capacitance for each quartz component is defined in the specification. The load capacitance is the capacitance to which a quartz crystal is most exactly matched during production. Here the crystal is excited into oscillation, the frequency is measured and if necessary the mass of the silver electrode is corrected by evaporation deposition or erosion (by bombardment with ions).

在晶振生产端,为确保在 25°C 下符合频率,规范中定义了每个石英晶体元件的负载电容。负载电容是石英晶体在生产过程中最精确匹配的电容。在这里,晶体被激发振荡,测量频率,如有必要,通过喷射背银或蚀刻(通过离子轰击)校正银电极的质量。

If the active CL is achieved again exactly during this matching in the final circuit, the crystal will oscillate reliably at room temperature at its nominal frequency.

如果在最终电路应用中,该负载电容实现准确匹配的话,晶体谐振器将在室温下稳定输出其标称频率(如: ±10ppm)。

For developers, this matching brings with it the problem that they usually do not know what error is being introduced to the measurement by the crystal currently being used. Without knowing this, it is impossible to perform a precise matching. If the matching is performed in the laboratory of the quartz supplier, it is generally the frequency deviation brought by the individual crystal that is measured and subsequently compensated. Alternatively, developers who wish to make a precise matching themselves can obtain measured samples from the supplier so that the errors introduced can be compensated.

对于开发人员来说,这种匹配带来了一个问题,即他们通常不知道当前使用的晶体在测量中引入了什么误差。若不知道这一点,就不可能进行精确匹配。如果匹配是在石英供应商的实验室中进行的,则通常是单个晶体带来的频率偏差。若通过电路板上电进行负载电容的精确匹配,开发人员可以从晶振供应商处获取晶振样品及测试数据,以便分析并评估引入的误差。