Comparing the differences between AT and SC crystals and their impact on oscillator performance 比较AT切和SC切晶体之间的差异及其对晶体振荡器性能的影响

Inside of every quartz oscillator is something called a crystal blank. The crystal blank is the resonating element of the oscillator that when subjected to a voltage potential will begin to vibrate and oscillate at it’s “fundamental frequency.” As you can probably imagine, the way that crystal blank is manufactured can have a significant impact on the oscillators performance. One of the most impactful manufacturing steps to crystal, and therefore oscillator performance, is the orientation of the quartz when the crystal blank is cut.

在每个石英振荡器的内部都有一个叫做石英晶片的东西。石英晶片是振荡器的谐振元件,当受到电压差作用时,它将开始振动并以“基频”模式振荡。正如您可能想象的那样,石英晶片的制造工艺会对振荡器的性能产生重大影响,而其中的关键因素是石英晶体的切割角度。

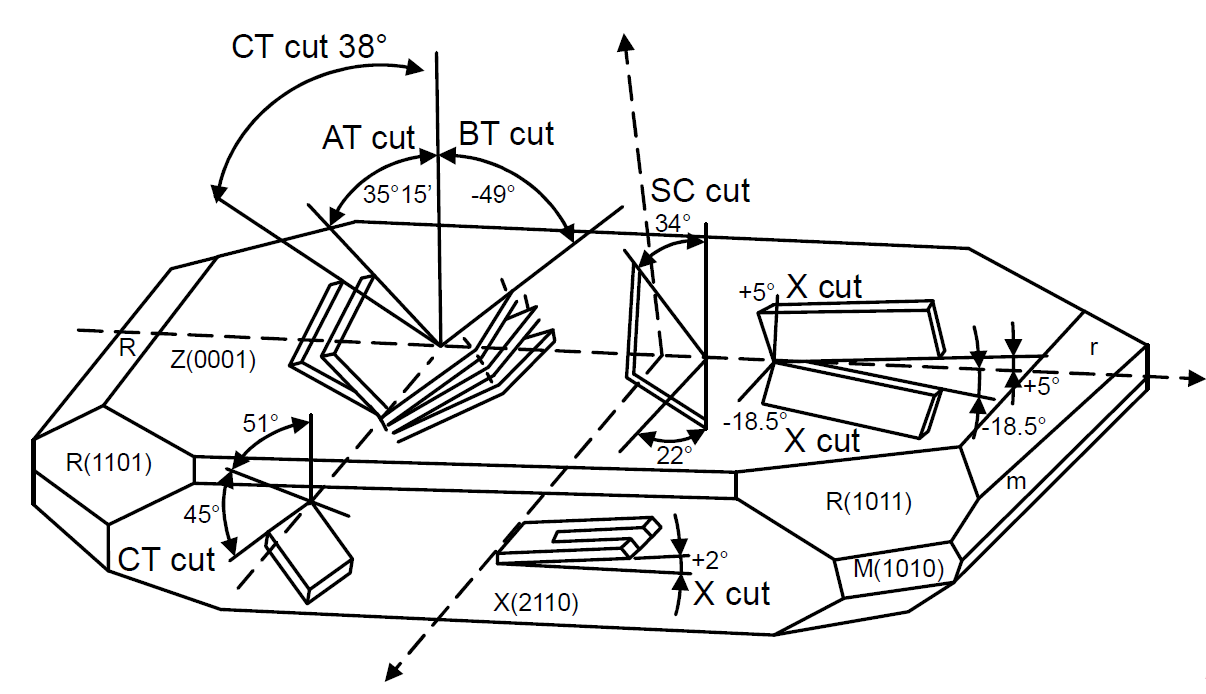

The crystal blank is cut from a larger piece of bulk quartz and since quartz is a crystal the internal structure of the material is a predicable lattice structure. Therefore, the orientation or angle of the lattice structure can create different ‘cuts’ of crystal blanks. Two of the most common quartz crystal cuts used in OCXOs (oven controlled oscillators) are AT cuts and SC cuts.

石英晶片是从一块较大的块状石英晶体中切割而成。由于石英为晶格结构,因此我们可以根据晶格结构的方向或角度,生产出不同切割角度的晶片,比如:OCXO(恒温晶体振荡器)中使用的石英晶体,其最常见的切割方式为AT切和SC切两种形式。

The AT is a temperature compensated cut, meaning the cut is oriented such that the temperature coefficients of the lattice will have minimal impact on crystal performance.

AT是温度补偿切割,这意味着切割的方向使得晶格的温度系数对晶体性能的影响最小。

The SC (stress compensated) is also temperature compensated. Originally developed in 1974, the SC cut is a double rotated cut.

SC(应力补偿)也是温度补偿的。SC 切割最初于 1974 年开发,是一种双旋转切割。

When selecting an oscillator for a specific application, it is important to understand the type of crystal at the heart of the oscillator. The key parameters that differ between AT cuts and SC cuts are frequency vs. temperature stability, crystal aging, g-sensitivity, initial frequency accuracy, availability, and cost.

在为特定应用选择晶体振荡器时,首先了解置于振荡器内部的晶体的切割类型非常重要。AT切晶片和SC切晶片之间,存在的差异往往体现在以下关键参数:频率与温度稳定性、晶体老化、g灵敏度、初始频率精度、可用性和价格成本。

![]() Frequency vs. Temperature温度频差

Frequency vs. Temperature温度频差

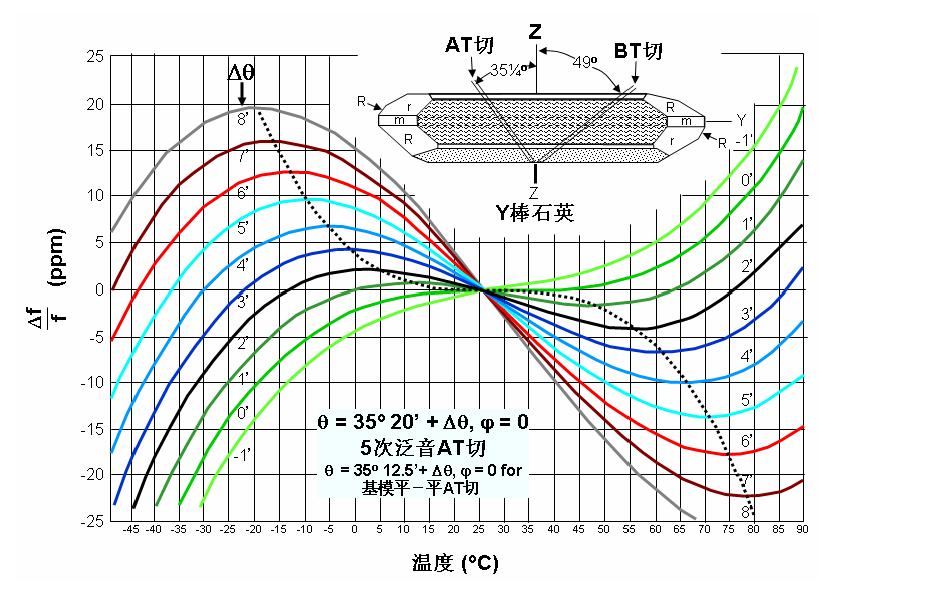

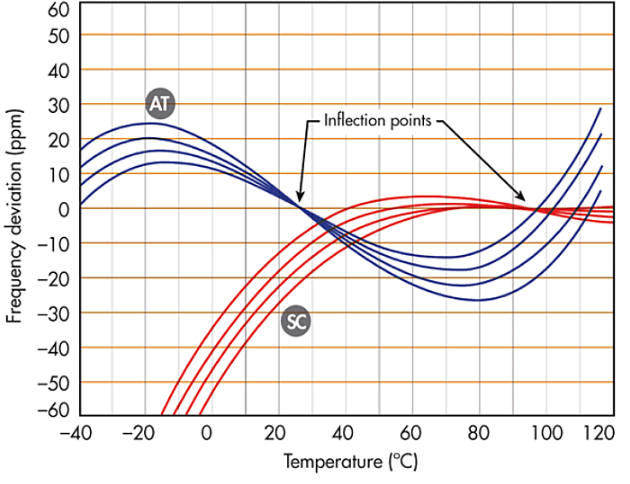

Frequency vs. temperature stability is a spec that describes how the frequency output of the oscillator changes over temperature. FvT performance is measured in parts per billion or PPB. The SC cut will deliver improved performance in the oscillator. Main reason is the slope of the curve in the vicinity of the crystal’s turning point. Typically, the slope of the SC cut is 1/3rd that of an AT cut with same turning point. Another area where the SC cut delivers improved FvT performance is operation at elevated temperature ranges (-20C to +200℃) seen in downhole applications. With an inflection temperature of approximately +90℃ compared to +27℃ for AT, the SC will achieve tighter stability over these ranges. The improvement could be as much as 5X over this extended temperature range.

温度频差是一个规范,用于描述晶体振荡器的频率输出如何随温度变化。温度频差的性能以十亿分之一或 PPB 为单位。SC 切晶片提高了晶体振荡器的性能,其主要原因取决于频率变化曲线位于晶体转折点附近的斜率。通常,SC 切割晶体的斜率为具有相同转折点的 AT 切割的晶体的三分之一。SC切晶体方式大大优化了晶体振荡器的温频特性,因此确保了其应用设备可以在井下高温范围内(-20℃至+200℃)正常运行。与AT切晶体的拐点温度约为+90℃相比,SC的拐点温度约为+27℃,因此SC切晶体将在这些范围内实现更严格的稳定性,其改进程度可能高达5倍。

![]() Crystal Aging晶体老化

Crystal Aging晶体老化

The crystal aging is a spec that describes how the frequency of the crystal changes over the life of the crystal. Crystal aging occurs as a result of impurities within the oscillator. Aging is measured in PPM or PPB. The SC cut is less sensitive to some of the aging effects, such as crystal mount stresses, crystal blank plating stresses, changes in performance of the electronics, etc.

晶体老化是一个规范,描述了晶体的频率在晶体的使用寿命中如何变化。晶体老化是振荡器内部含有杂质的结果。老化以PPM或PPB为单位。SC切晶体对某些老化效应不太敏感,例如晶体安装应力,晶片电镀应力及电子设备性能变化等。

![]() G-sensitivity G 灵敏度

G-sensitivity G 灵敏度

G-sensitivity describes the impact of shock and vibration to the frequency output of the oscillator. G-sensitivity is measured in PPB/G. Because the quartz crystal is an electro-mechincal device that vibrates under a voltage potential, introducing a vibration can cause the electrical output characteristics to change. In fact, g-sensitivity is a major contributor to the phase noise of an oscillator.

G灵敏度描述了冲击和振动对振荡器频率输出的影响。G灵敏度以PPB/G为单位测量。由于石英晶体是在电压下振动的频率器件,因此引入振动会导致电输出特性发生变化。事实上证明,G灵敏度是造成晶体振荡器相位噪声的主要因素。